REDICE ACTIVE IMPLANT

RAI is the optimal solution for immediate implantation and immediate loading.

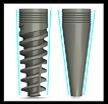

The RAI implant has exceptional self-drilling capabilities and a unique spiral body design which enables it to change its position during placement and obtain very high primary stability even in very complicated clinical cases.

Cover screw is included

One micron level between implant and abutment (Microgap) between the implant platform and the abutment is kept to an absolute minimum.

Rough surface on the top. Threads reaching the top of the implant.

Advantage: Decreasing the crestal stress

Tapered body and code. V Shape Body

Design.

Advantage: Very Easy Implant Insertion.

Expanding tapered implant body with double-thread self tapping design

condenses bone gradually to enhance primary stability.

Rounded apex improves the ease of insertion and allowing mild direction

refinement during the initial stages of insertion

INTERNAL HEX CONNECTION

Compatilbe with other major brands

Hex size 2.42mm

Single Platform connection for all implant diameters

Material – Titanium Ti-6AL-4V-ELI (Ti Grade 5)

SLA Surface Treatment

Platform switch design

Perfect for two stage implantation

INTERNAL HEX CONNECTION

High and consistent survival rates,

over 96% after a 10 years follow up

Average bone loss of <1 mm after

7 years (based on the implant loading time)

NO PERI-IMPLANTITIS – Very low prevalence

of peri-implantitis over the 7 years followup period

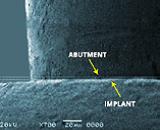

Implant-Abutment connection

We at Redice Implant LTD, believe that the esthetics and long-term success of the final restoration are greatly influenced by the design of the implant-abutment connection. The well trusted design of the internal hexagon connection is further strengthened by our ALS™ (Advanced Locking System) concept which

incorporates very tight manufacturing tolerances in 3 critical parameters

Mating Tolerances

Roundness Surface

Roughness

The Spiral Shape Implant (SSI) production process is specifically designed to tightly control

these 3 key elements and in turn provide:

Maximal rotational Precision

This means that the implant position recorded by the impression coping will be accurately reproduced on the laboratory model, thereby ensuring that the final restoration will be aligned exactly as intended. In addition, the risk of loosening abutment screw is greatly reduced

Minimal microgap

“Microgap” between the implant platform and the abutment is kept to an absolute minimum. This has the clinical benefit of reducing the possibility of bacterial contamination and improving the long term bone level stability

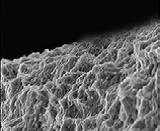

A REDICE ACTIVE IMPLANT

under up to x700 magnification (SEM).

SLA Surface Treatment

All REDICE Implants feature a blasted and thermally acid-etched endosseous surface. The micro and macro structure achieved by this process facilitates an accelerated osseointegration of our implants.

A REDICE IMPLANT

under up to x84,000 magnification (SEM)