QUICK IMPLANT SIZE IDENTIFICATION

| REGULAR PALTFORM ( REDICE ACTIVE ) | |||||

| Length/Diameter | Ø 3.3 | Ø 3.75 | Ø 4.20 | Ø 5.0 | Ø 6.0 |

| 6.0mm L | RA37506 | RA4206 | RA5006 | RA6006 | |

| 8.0mm L | RA3308 | RA37508 | RA4208 | RA5008 | RA6008 |

| 10.0mm L | RA3310 | RA37510 | RA4210 | RA5010 | RA6010 |

| 11.5mm L | RA33115 | RA375115 | RA42115 | RA50115 | RA60115 |

| 13.0mm L | RA3313 | RA37513 | RA4213 | RA5013 | RA6013 |

| 16.0mm L | RA3316 | RA37516 | RA4216 | RA5016 | RA6016 |

Hex 2.42

SINGLE PROSTHETICAL PLATFORM

The RDI Internal hex diameters utilize one line of prosthetic components.

DRILLING PROTOCOL

3.3

- Drill sequence by bone type – An additional 1 mm must

be added to the length of the drill to account for the angled

cutting tip. - D-I, D-II Dense bone considerations – Countersink

should be used if the standard dense bone protocol is not

sufficient to fully seat the implant without exceeding the

recommended maximum insertion torque of max. 60Ncm

for implant Ø3.75mm and above. Do not exceed max.

45Ncm for implants diameter lower than 3.75mm.

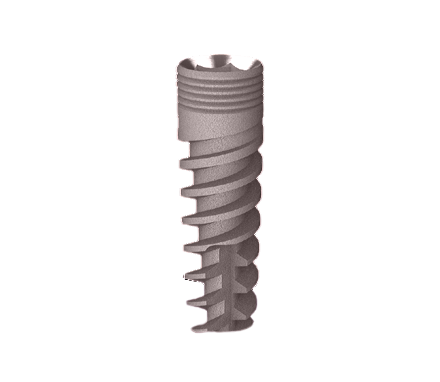

DRILLING PROTOCOL

3.75

- Drill sequence by bone type – An additional 1 mm must

be added to the length of the drill to account for the angled

cutting tip. - D-I, D-II Dense bone considerations – Countersink

should be used if the standard dense bone protocol is not

sufficient to fully seat the implant without exceeding the

recommended maximum insertion torque of max. 60Ncm

for implant Ø3.75mm and above. Do not exceed max.

45Ncm for implants diameter lower than 3.75mm.

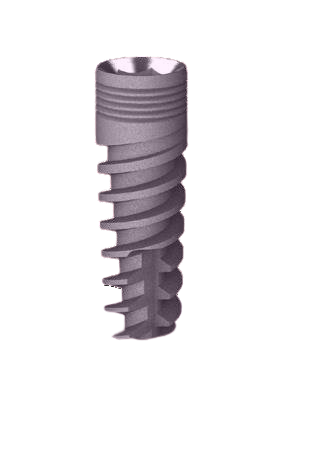

DRILLING PROTOCOL

4.2

- Drill sequence by bone type – An additional 1 mm must

be added to the length of the drill to account for the angled

cutting tip. - D-I, D-II Dense bone considerations – Countersink

should be used if the standard dense bone protocol is not

sufficient to fully seat the implant without exceeding the

recommended maximum insertion torque of max. 60Ncm

for implant Ø3.75mm and above. Do not exceed max.

45Ncm for implants diameter lower than 3.75mm.

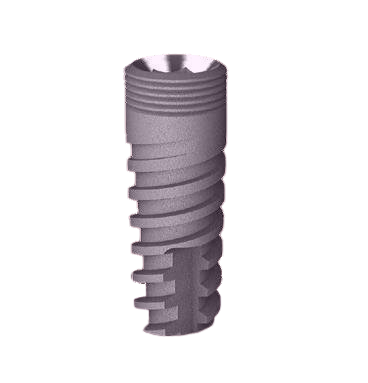

DRILLING PROTOCOL

5.0

- Drill sequence by bone type – An additional 1 mm must

be added to the length of the drill to account for the angled

cutting tip. - D-I, D-II Dense bone considerations – Countersink

should be used if the standard dense bone protocol is not

sufficient to fully seat the implant without exceeding the

recommended maximum insertion torque of max. 60Ncm

for implant Ø3.75mm and above. Do not exceed max.

45Ncm for implants diameter lower than 3.75mm.

DRILLING PROTOCOL

6.0

- Drill sequence by bone type – An additional 1 mm must

be added to the length of the drill to account for the angled

cutting tip. - D-I, D-II Dense bone considerations – Countersink

should be used if the standard dense bone protocol is not

sufficient to fully seat the implant without exceeding the

recommended maximum insertion torque of max. 60Ncm

for implant Ø3.75mm and above. Do not exceed max.

45Ncm for implants diameter lower than 3.75mm.